Wire Size / Ampacity Calculator

Choosing the correct wire size is critical for electrical safety and performance. Our Wire Size & Ampacity Calculator helps you quickly determine the recommended AWG wire gauge based on amps, or find the maximum amp rating for a selected wire size. Whether you’re asking “What wire gauge do I need for 20 amps?” or comparing copper vs aluminum wire ampacity, this tool provides fast, NEC-based reference values with both AWG and mm² cross-section equivalents. Select your conductor material, temperature rating, and calculation mode below to find the correct wire size or ampacity for your application.

Wire Size & Ampacity Calculator

The Complete Guide to Wire Size, Ampacity, and Electrical Safety

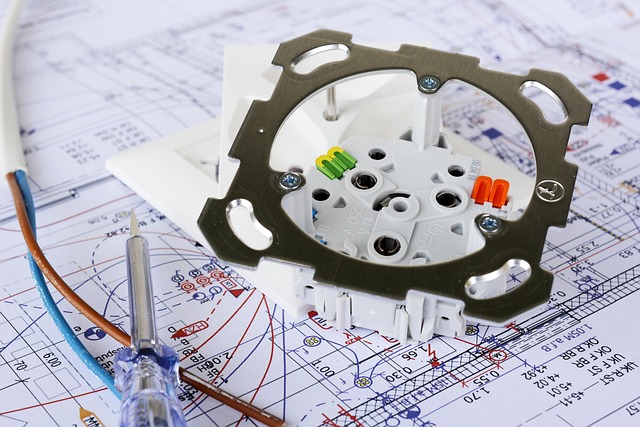

Choosing the correct wire size is one of the most important decisions in any electrical installation. Whether you’re wiring a residential circuit, installing a subpanel, running a new outlet, or sizing conductors for equipment, selecting the proper wire gauge directly impacts safety, performance, and code compliance.

If you’ve used the Wire Size & Ampacity Calculator above, you already have a quick estimate of the recommended AWG size or maximum amp rating. But understanding how wire sizing works — and why it matters — will help you make safer and more informed decisions.

This comprehensive guide explains everything you need to know about wire gauge, ampacity, copper vs aluminum conductors, NEC ampacity rules, temperature ratings, voltage drop considerations, breaker sizing, and common mistakes in electrical wire sizing.

What Is Wire Ampacity?

Ampacity refers to the maximum amount of electrical current a conductor can carry continuously without exceeding its temperature rating.

When electrical current flows through a wire, resistance causes heat. If the wire is too small for the current load, excessive heat builds up. Over time, this can:

Damage insulation

Degrade conductor material

Cause breaker trips

Create fire hazards

That is why correct wire sizing is essential for electrical safety.

What Does AWG Mean?

AWG stands for American Wire Gauge. It is the standardized system used in the United States to measure conductor size.

In the AWG system:

Smaller numbers mean thicker wires

Larger numbers mean thinner wires

For example:

14 AWG is thinner than 12 AWG

12 AWG is thinner than 10 AWG

2 AWG is much thicker than 10 AWG

After 1 AWG, sizes continue as:

1/0 (one aught)

2/0 (two aught)

3/0

4/0

Thicker wires have lower electrical resistance and can safely carry more current.

Why Proper Wire Size Matters

Using the correct wire size prevents:

Overheating

Voltage drop problems

Nuisance breaker trips

Code violations

Electrical fires

An undersized conductor may work temporarily, but over time insulation can break down due to heat stress. That’s why electrical codes strictly regulate wire amp ratings.

NEC Wire Ampacity Standards

In the United States, wire sizing is governed by the National Electrical Code (NEC).

The NEC provides ampacity tables that specify maximum allowable current for various conductor sizes based on:

Conductor material (copper or aluminum)

Temperature rating (60°C, 75°C, 90°C)

Installation conditions

For example, under typical 75°C residential conditions:

14 AWG copper = 20A

12 AWG copper = 25A

10 AWG copper = 35A

However, branch circuit rules often limit smaller conductors further:

14 AWG → 15A breaker

12 AWG → 20A breaker

10 AWG → 30A breaker

This is why breaker size and wire gauge must always be matched correctly.

Copper vs Aluminum Wire

Copper and aluminum conductors have different electrical properties.

Copper has lower resistance and higher conductivity. It carries more current per size and is commonly used in residential branch circuits.

Aluminum is lighter and less expensive but has higher resistance. For the same ampacity, aluminum wire must be larger than copper.

For example:

10 AWG copper may carry 35A

10 AWG aluminum may carry 30A or less

When selecting wire size, conductor material must always be considered.

Temperature Rating and Insulation

Wire ampacity depends heavily on insulation temperature rating.

Common ratings include:

60°C

75°C

90°C

Higher-rated insulation can handle higher temperatures and therefore higher ampacity — but only if all connected equipment is rated for that temperature.

In many residential panels, terminals are rated at 75°C, which limits usable ampacity even if the wire insulation is rated for 90°C.

Breaker Size and Wire Gauge Relationship

A breaker protects the wire — not the appliance.

The purpose of a circuit breaker is to trip before the wire overheats.

This means:

Breaker size must never exceed the wire’s safe ampacity.

For example:

12 AWG copper typically pairs with a 20A breaker.

Installing a 30A breaker on 12 AWG wire is unsafe and a code violation.

When asking “what wire gauge do I need,” the correct question is often:

What breaker size am I using?

Continuous Load Rule (80% Rule)

The NEC defines a continuous load as a load expected to run for three hours or more.

For continuous loads, the conductor must be sized at 125% of the load.

This means:

20A continuous load requires wire rated for at least 25A.

This is commonly called the 80% rule because a breaker should not carry more than 80% of its rating continuously.

Understanding this principle prevents overheating in commercial and high-duty installations.

Voltage Drop and Wire Length

Ampacity is not the only factor in wire sizing. Voltage drop becomes critical over long distances.

Voltage drop occurs when resistance reduces voltage at the load end.

Excessive voltage drop can:

Reduce motor efficiency

Cause dim lighting

Damage electronics

Overheat equipment

A common recommendation is:

Limit voltage drop to 3% per branch circuit.

Longer wire runs may require upsizing the conductor even if ampacity is sufficient.

Example: What Wire Gauge Do I Need for 20 Amps?

Under typical residential 75°C conditions:

12 AWG copper is recommended for 20A circuits.

If the run is very long (for example, over 100 feet), upsizing to 10 AWG may reduce voltage drop.

Always consider:

Breaker size

Distance

Conductor material

Temperature rating

Wire Size for 30A, 40A, 50A Circuits

Common examples:

30A → 10 AWG copper

40A → 8 AWG copper

50A → 6 AWG copper

However, aluminum equivalents require larger gauges.

Always verify ampacity tables and local code requirements.

Common Wire Sizing Mistakes

Undersizing wire to save cost

Ignoring voltage drop

Mixing copper and aluminum incorrectly

Installing oversized breakers

Ignoring temperature rating limits

Using extension cord ampacity as building wiring reference

Professional installations follow code tables strictly to avoid these issues.

Low Voltage vs Branch Circuit Wiring

Smaller wires like 18 AWG and 16 AWG are often used for:

Control circuits

Thermostats

Automotive wiring

Low voltage lighting

Electronics

These are not typically used for 120V or 240V branch circuits.

Different ampacity rules apply to chassis wiring vs building wiring.

Electrical Safety and Fire Prevention

According to fire safety studies, electrical failures are a leading cause of residential fires.

Many of these incidents trace back to:

Improper wire sizing

Loose connections

Overloaded circuits

Incorrect breaker pairing

Correct wire sizing is one of the simplest ways to reduce risk.

When to Consult an Electrician

You should consult a licensed electrician when:

Installing new service panels

Running subpanels

Installing EV chargers

Wiring large appliances

Modifying existing circuits

Unsure about local code compliance

While calculators provide guidance, final installations must comply with local regulations.

Final Thoughts on Choosing the Right Wire Size

Selecting the correct wire gauge is not just about matching amps to AWG. It requires understanding conductor material, insulation temperature rating, breaker sizing, voltage drop, continuous load rules, and NEC standards.

The Wire Size & Ampacity Calculator above provides a fast and practical reference tool. However, electrical safety depends on applying these values correctly in real-world installations.

When in doubt, choose the safer option, verify with local electrical code, and consult a qualified professional.

Electrical systems operate silently — until something goes wrong. Proper wire sizing ensures they remain safe, efficient, and reliable for years to come.

The images in this article were created using artificial intelligence or sourced from lawful, freely usable providers — such as Pixabay or Pexels.